Computed Digital Radiography Test(CR)

A.Purpose

The computed digital radiography (CR) is quite similar to the conventional film radiography testing, yet it has several advantages as followings.

- The results of CR are quickly and directly after exposure, it could be schedule up the engineering progress.

- CR image is more convenient for analysis, high accuracy and better reproducibility.

- There is no film conservation disadvantage (storage space, review, contaminant, humility..)

- Corrosion survey on pipes through insulation has higher accuracy.

- There is no need a dark room for film processing.

- The shorter exposure time and less radiation dose are needed.

|

B.Application

Flaw detecting, sizing and corrosion mapping of weld, piping, material and parts in various industrial fields..

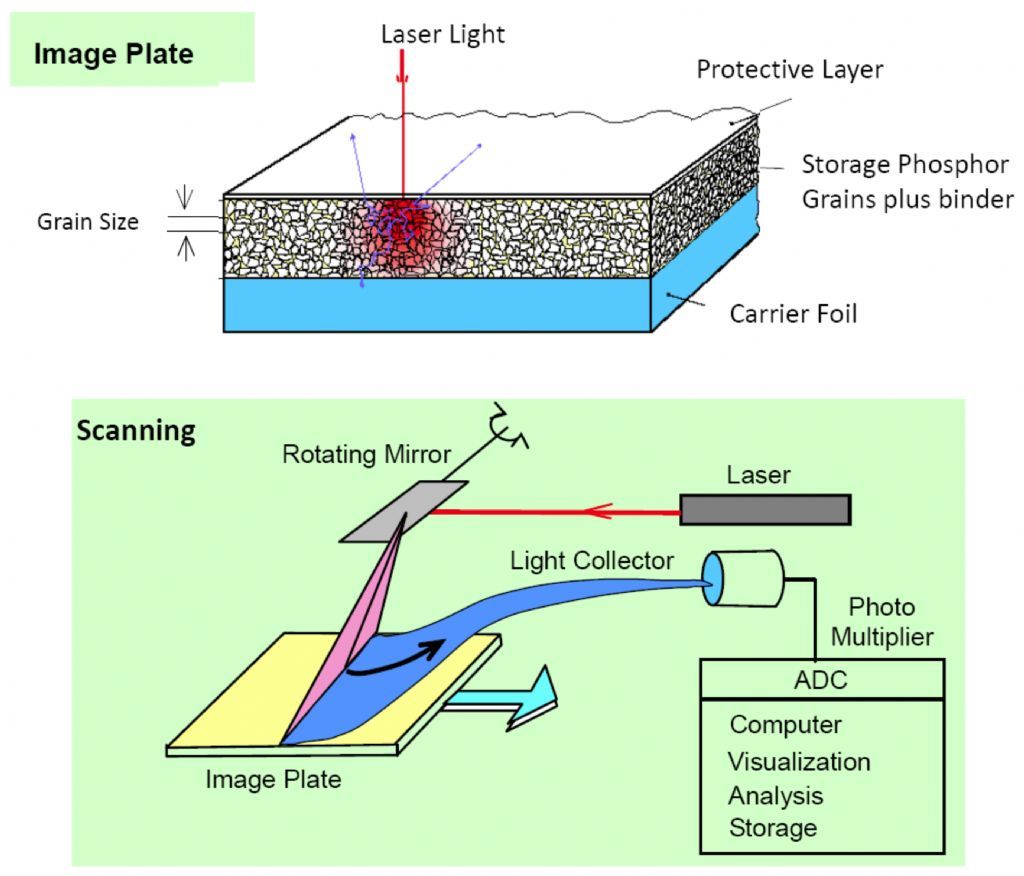

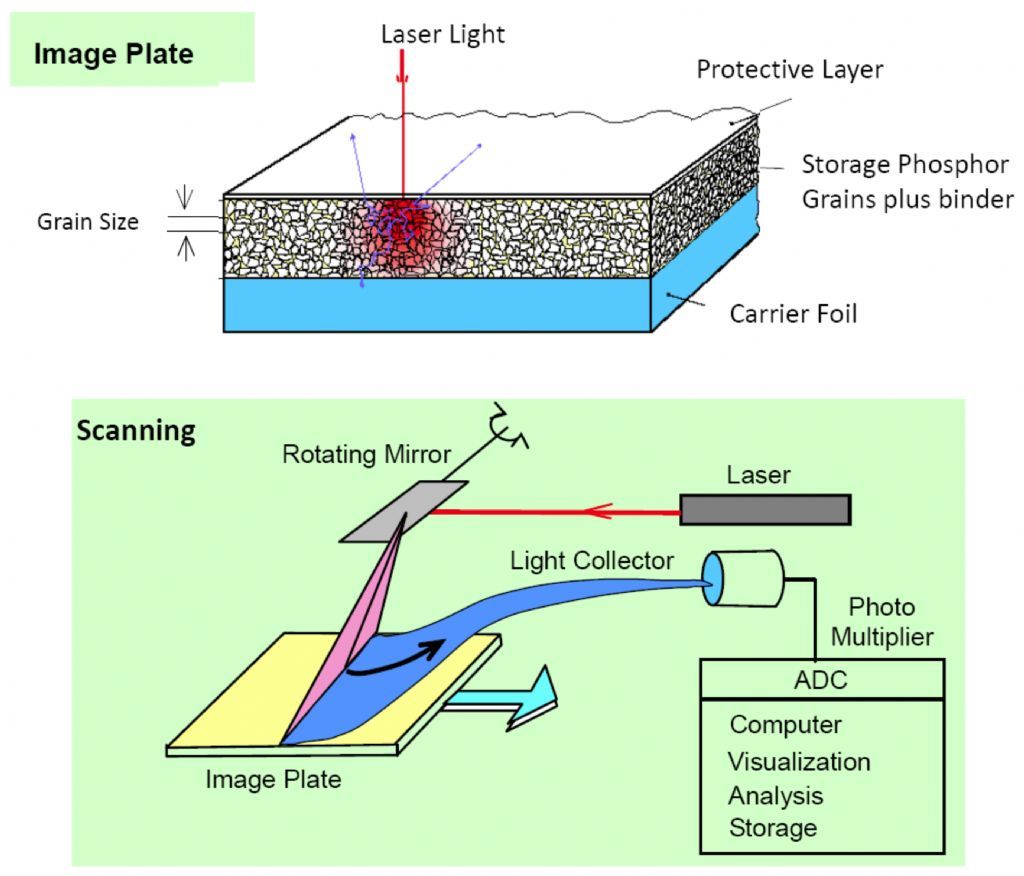

C.Principle of computed radiography imaging

A photostimulable storage phosphors structure as CR imaging plate (IP), which stores the radiation level received at each point in local election energies. When the IP subjects to laser scanning, IP will emit light and detected by a photo-multiplier tube. The photo-multiplier tube is then converted to an electronic signal. The electronic signal is then converted to digital value and display image on computer.

|