Hardness Test

- 文章分類: 英文-服務項目

- 6/1/2011

A.PurposeTo measure the hardness condition of a material as made condition, heat treatment procession and in-service variation….etc. With the information, we can understand the results of processed for our evaluation.B.Application

|

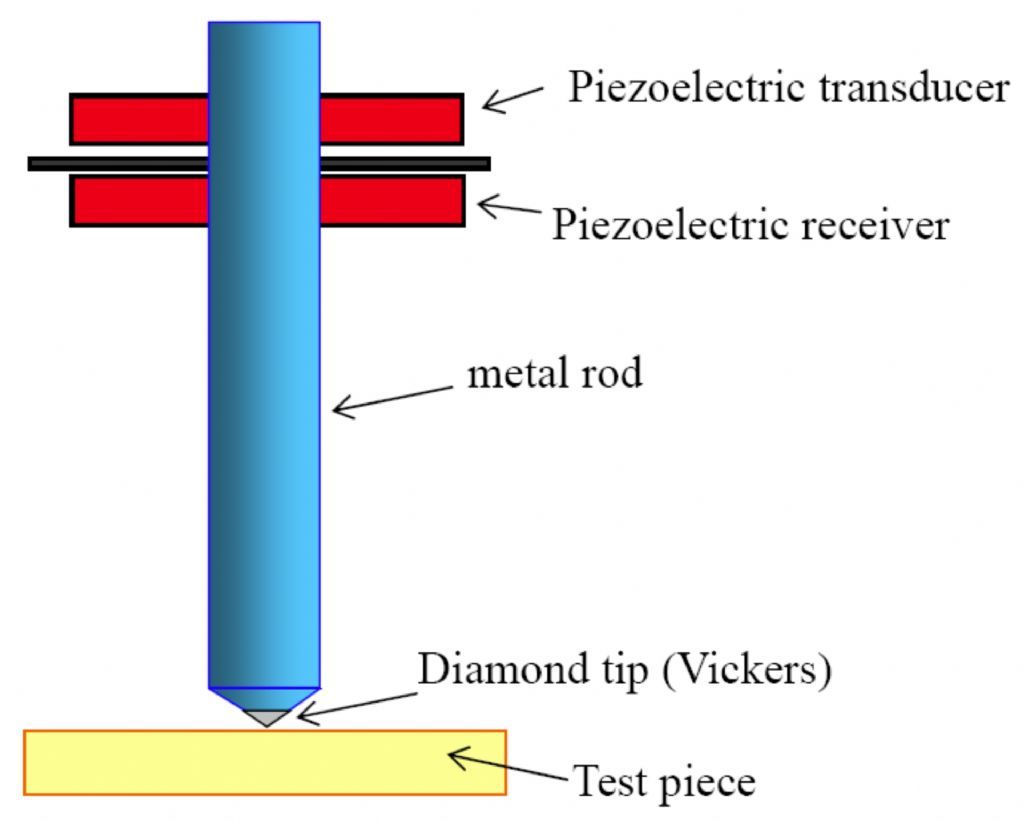

C.PrincipleThere are several hardness test methods such as Brinell (HB), Rockwell (HR), Shore (HS), Vickers (HV) and Leeb (HL). All methods use a probe (steel ball, indenter or diamond tip) at a rated load on the test surface, after release the load the diameter of indentation, diagonal length, and rebound height is investigated, and then calculates into a hardness value. A latest hardness test method applied the ultrasonic impedance. It use a metal rod with a diamond tip at front to excite into longitudinal oscillation by a ceramic piezoelectric transducer at an ultrasonic frequency. When the test load is applied, a frequency shift occurs as proportional to diamond penetrates into the metal. Then electronic detected by piezoelectric receiver measures the shift of an ultrasonic frequency and convert to hardness value. |